+91 8008404021

Energy Audit

As per the Energy Conservation Act, 2001, an energy audit involves the verification, monitoring, and analysis of energy use, along with recommendations to improve efficiency through a cost-benefit approach.

With energy costs ranking among the top three expenses in most industries, effective energy management is key to reducing operational costs. Energy audits help identify where energy is being wasted and highlight areas for improvement.

At Saurashakti Energies, we go beyond just reporting. Our team works with you to turn insights into action-helping you optimize energy use, reduce costs, and build a more efficient, sustainable operation.

Mandatory Energy Audits for High-Power Consumers:

The Energy Conservation Act provides for a biennial energy audit of Designated Consumers in various industrial sectors consuming more energy per year than the threshold defined by Bureau of Energy Efficiency (BEE), Ministry of Power, Government of India.

Our commitment is driven by three core principles:

- We engineer solutions that drive sustainability and long-term value.

- We collaborate with a unified vision to power progress.

- We care deeply about our people, partners, and the planet.

What is Industrial Energy Audit?

Industrial Energy Audit is a comprehensive investigation into the energy consumption of a manufacturing facility. It systematically analyses each stage of the production process, from raw material intake to finished product, with the objective of identifying areas where energy is wasted and pinpointing opportunities for significant cost savings. This analysis encompasses equipment efficiency, process optimization, and resource utilization, aiming to minimize environmental impact and boost operational efficiency.

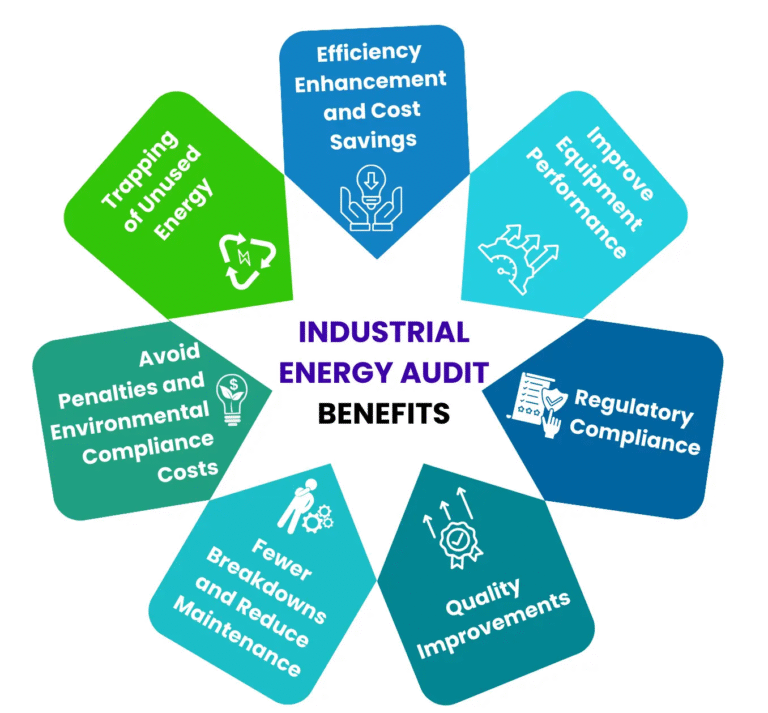

Benefits of Industrial Energy Audit?

Reduced energy costs: Identify and eliminate energy waste, leading to significant financial savings on your utility bills.

Improved environmental footprint : Minimize your carbon footprint by optimizing energy consumption and transitioning to renewable energy sources.

Enhanced process efficiency: Identify and address equipment inefficiencies, boosting production output and quality.

Informed decision-making : Gain accurate data and insights to guide strategic investments in energy-saving technologies and upgrades.

Increased competitive advantage: Demonstrate a commitment to sustainability and cost-effectiveness, enhancing your market appeal.

Applications of Industrial Energy Audit Services

Manufacturing facilities : across diverse industries like food and beverage, chemical, textile, and automotive.

Power plants and refineries : Optimizing energy generation and consumption for maximum efficiency.

Water treatment facilities : Minimizing energy use in water pumping, purification, and distribution.

Mining and processing operations : Identifying energy-saving opportunities in resource extraction and processing.

Any industrial facility with complex energy systems and high energy consumption.

Reduced energy costs

Improved environmental footprint

Enhanced process efficiency

Informed decision-making

Increased competitive advantage

Grid connection

What is an Industrial Energy Audit?

Industrial Energy Audit is a comprehensive investigation into the energy consumption of a manufacturing facility. It systematically analyses each stage of the production process, from raw material intake to finished product, with the objective of identifying areas where energy is wasted and pinpointing opportunities for significant cost savings. This analysis encompasses equipment efficiency, process optimization, and resource utilization, aiming to minimize environmental impact and boost operational efficiency.

Benefits of Industrial Energy Audit?

Reduced energy costs: Identify and eliminate energy waste, leading to significant financial savings on your utility bills.

Improved environmental footprint: Minimize your carbon footprint by optimizing energy consumption and transitioning to renewable energy sources.

Enhanced process efficiency: Identify and address equipment inefficiencies, boosting production output and quality.

Informed decision-making: Gain accurate data and insights to guide strategic investments in energy-saving technologies and upgrades.

Increased competitive advantage: Demonstrate a commitment to sustainability and cost-effectiveness, enhancing your market appeal.

Applications of Industrial Energy Audit Services

Manufacturing facilities: across diverse industries like food and beverage, chemical, textile, and automotive.

Power plants and refineries: Optimizing energy generation and consumption for maximum efficiency.

Water treatment facilities: Minimizing energy use in water pumping, purification, and distribution.

Mining and processing operations: Identifying energy-saving opportunities in resource extraction and processing.

Any industrial facility with complex energy systems and high energy consumption.

Industrial Energy Audit Services Offers

- Recommendations to reduce energy consumption and achieve cost savings

- Identify areas of energy waste and inefficiency

- Implement targeted solutions to reduce energy consumption

- Lower operating costs and utility bills

- Gain insights into energy consumption patterns and trends

- Contribute to environmental sustainability by reducing carbon emissions

- Align with green initiatives and corporate social responsibility

- Compliance with energy efficiency standards and regulations

- Address specific challenges and opportunities for improvement

- Adapt to changing energy landscapes and future-proof your operations

Energy audit means the verification, monitoring and analysis of use of energy including submission of technical report containing recommendations for improving energy efficiency with cost benefit analysis and an action plan to reduce energy consumption.

It is a crucial step because it provides a means for identifying the most energy consuming areas and solution to reduce the energy consumption thereby increasing energy efficiency. With energy auditing one can easily reduce energy bill between 5% to 25%. Energy Auditing is done by accredited energy auditor which means an auditor possessing qualifications.

Our Industrial Energy Audit Services entail:

- Comprehensive on-site walk-through with a certified Energy Auditor to identify areas that need improvement.

- In-depth consultations to align your energy goals with your current operational status.

- Comprehensive facility inspections reveal inefficiencies across energy, thermal and power systems.

- Expert recommendations providing clear, actionable strategies to maximize efficiency and reduce energy costs.

Types of Energy Audit

The types of Energy Audit to be performed depends on :

1. Function and type of industry.

2. Depth to which final audit is needed, and Potential and magnitude of cost reduction.

Thus, Energy Audits can be classified into the following two types.

Preliminary Audit and Detailed Audit

Preliminary Energy Audit Methodology

Preliminary energy audit is a relatively quick exercise to :

1. Establish energy consumption in the organization.

2. Estimate the scope for saving.

3. Identify the most likely and the easiest areas for attention Identify immediate (especially no-/low-cost) improvements/ savings.

Set a 'Reference point'

Identify areas for more detailed study/measurement

Preliminary energy audit uses existing, or easily obtained data

Detailed Energy Audit Methodology

A comprehensive audit provides a detailed energy project implementation plan for a facility, since it evaluates all major energy using systems. This type of audit offers the most accurate estimate of energy savings and cost. It considers the interactive effects of all projects, accounts for the energy use of all major equipment, and includes detailed energy cost saving calculations and project cost.

In a comprehensive audit , one of the key elements is the energy balance. This is based on a inventory of energy using systems, assumptions of current operating conditions and calculations of energy use. This estimated use is then compared to utility bill charges.

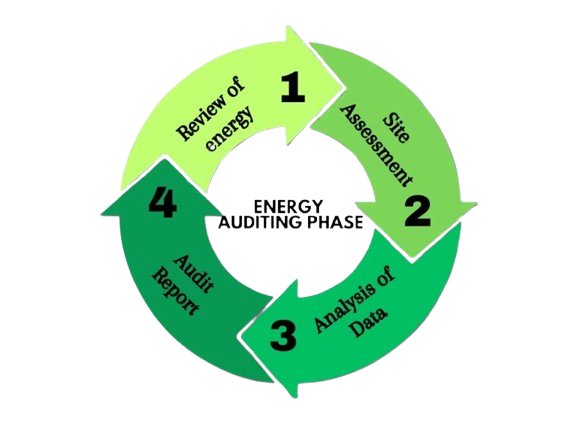

Detailed energy auditing is carried out in three phases: Phase I, II and III.

Phase I - Pre Audit Phase

Phase II - Audit Phase

Phase III - Post Audit Phase

Type of Energy Audit

The type of Energy Audit to be performed depends on

- Function and type of industry

- Depth to which final audit is needed, and Potential and magnitude of cost reduction desired

Types of Energy Audit

The types of Energy Audit to be performed depends on:

- Function and type of industry.

- The depth of the final audit should correspond to the potential and magnitude of cost reduction.

Thus, Energy Audits can be classified into two types:

Preliminary Audit and Detailed Audit.

Preliminary Energy Audit Methodology

Preliminary energy audit is a relatively quick exercise to:

- Establish energy consumption in the organization.

- Estimate the scope for saving.

- Identify the most likely and the easiest areas for attention Identify immediate (especially no-/low-cost) improvements/ savings.

Detailed Energy Audit Methodology

A comprehensive audit provides a detailed energy project implementation plan for a facility, since it evaluates all major energy using systems. This type of audit offers the most accurate estimate of energy savings and cost. It considers the interactive effects of all projects, accounts for the energy use of all major equipment, and includes detailed energy cost saving calculations and project cost.

In a comprehensive audit , one of the key elements is the energy balance. This is based on a inventory of energy using systems, assumptions of current operating conditions and calculations of energy use. This estimated use is then compared to utility bill charges.

Detailed energy auditing is carried out in three phases:

Detailed energy auditing is carried out in three phases: Phase I, II and III.

Phase I – Pre Audit Phase

Phase II – Audit Phase

Phase III – Post Audit Phase